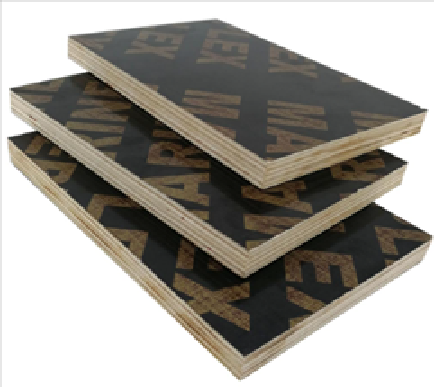

Plywood

1.Plywood is a versatile composite material commonly used in construction and woodworking. Let’s delve into its details:

Composition and Manufacturing:

1.Plywood is crafted from thin layers (plies) of wood veneer.

2.These veneer layers are glued together with adjacent layers, forming a strong and stable composite material.

3.The plies are oriented at right angles to each other, a technique known as cross-graining.

Cross-graining provides several benefits:

1.Reduced Splitting:

It minimizes the tendency of wood to split when nailed at the edges.

2.Dimensional Stability:

Plywood experiences less expansion and shrinkage, ensuring consistent dimensions.

3.Balanced Structure:

An odd number of plies balances the sheet, reducing warping.

Applications:

Plywood finds applications in various fields:

1.Construction:

Used for walls, roofs, floors, and formwork.

2.Furniture:

Plywood serves as a base material for cabinets, tables, and chairs.

3.Boat Building:

Marine-grade plywood withstands water exposure.

4.Interior Design

Plywood panels add texture and warmth to interiors. Packaging: Lightweight plywood is used for crates and boxes.

Types and Grades:

Plywood comes in different types based on wood species (e.g., hardwood, softwood) and intended use.

Grades indicate quality, with A being the highest and D being the lowest.

Common types include MR (Moisture Resistant), BWR (Boiling Water Resistant), and Marine Plywood3.

Advantages:

Strength: Plywood’s layered structure provides strength and stability.

Cost-Effective: It’s more affordable than solid wood.

Versatility: Suitable for various applications.

Eco-Friendly: Efficient use of wood resources

Easy to Work With: Can be cut, drilled, and shaped.